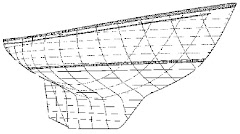

First, all the hardware had to come off. There is a lot of stuff on the deck of a Mason 44. Chainplate covers, stanchions, deck fills, hose bibs, blocks, track, etc. All this is through bolted, so the first step was to empty out the lockers and take down all of the headliners under the deck down below. Then everything has to be removed, numbered, bagged and stored. The result is a boat that looks like this:

While that was happening, Reggie and his helper were going over the deck, removing the thousands of screws that attached it to the fiberglass substrate. Some people don't remove the screws, but instead just cut them off. This is a bad idea - it leaves thousands of tiny holes in your deck, and, if you're doing paint or fiberglass rather than teak, the screws can print through the new surface over time. We've seen boats where this has happened, and it's not pretty. Some people will just pry the screws up when they remove the teak. Also a bad idea - you can actually delaminate the upper layer of fiberglass decking from the balsa core, and that's a very expensive and difficult thing to fix.

Then the teak has to be

Interestingly, we did not have fiberglass non skid under the teak. I'd heard that a lot of these boats did, as the non skid pattern was in the molds used to build the boat. On our boat, Ta Shing apparently ground it down before installing the teak. That's probably part of why the teak was so well stuck.

Once they got all of the mastic scraped/ground off of the fiberglass, it was time for one last grinding to smooth everything down, and they were ready to lay the new teak.

Oh, but what's that? This isn't teak caulk! It's teak cleaner. Crap! The distributor sent the wrong stuff down from San Diego. Luckily, Reggie was able to sell the cleaner to a marine business here in town, and the distributor got the (we hope) correct stuff on a truck that should get here tomorrow or Friday. So, for now, they're just dry fitting the planks. Once we have actual caulk, they'll move on to the next step, which is gluing them down. Stay tuned!

1 comment:

The deck is going to be beautiful when it is finished. What a project!

Post a Comment